A Certificate of Analysis is a detailed document that verifies the quality and composition of a product, ensuring it meets specified standards. It typically includes test results, batch numbers, and compliance information from a certified laboratory. Manufacturers and consumers rely on this certificate to guarantee product safety and consistency.

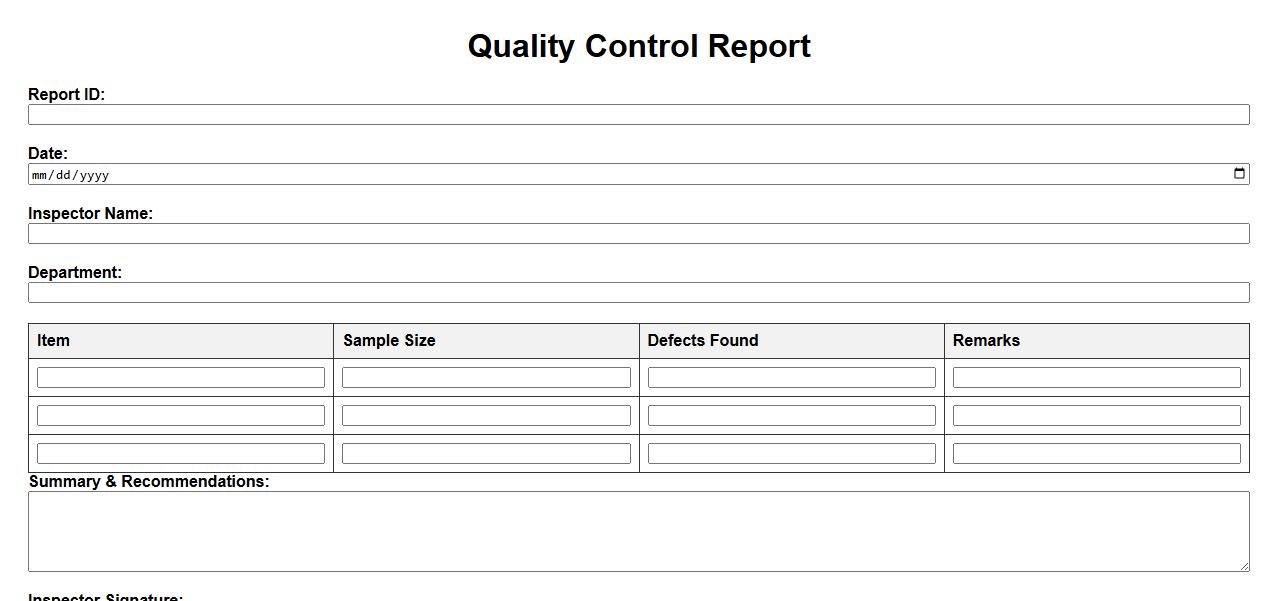

Quality Control Report

The Quality Control Report provides a detailed analysis of product standards and compliance with industry regulations. It highlights key inspection results and identifies any deviations from quality benchmarks. This report is essential for maintaining consistent production excellence and customer satisfaction.

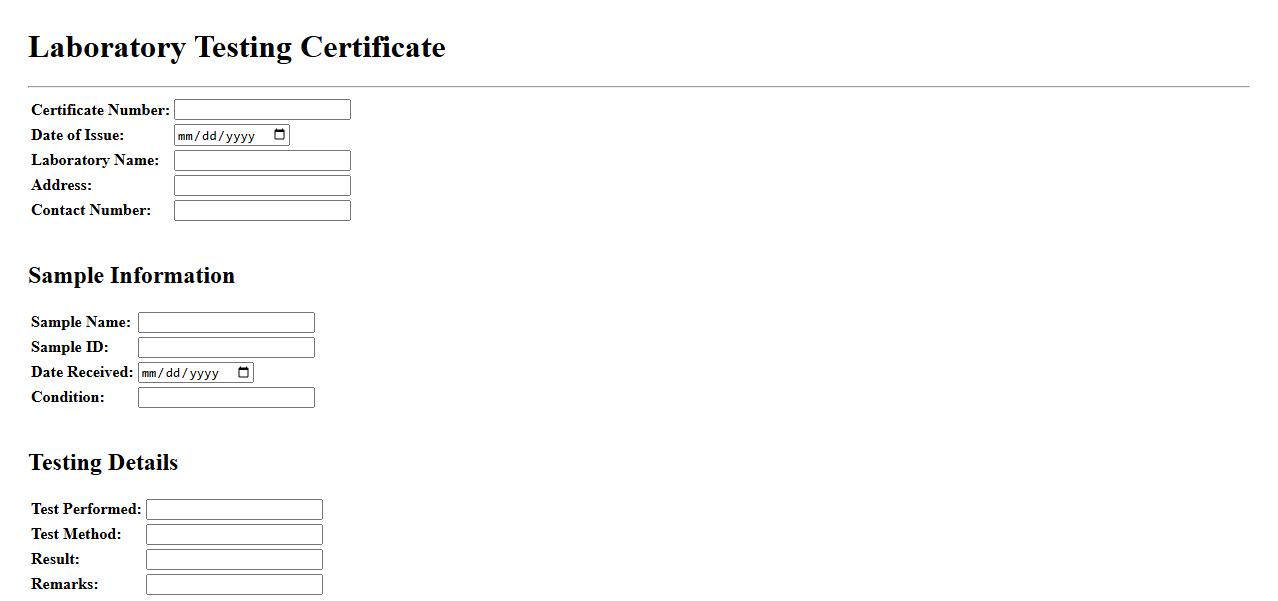

Laboratory Testing Certificate

A Laboratory Testing Certificate verifies that a product, material, or sample has undergone specific tests in a certified lab to meet quality and safety standards. This document confirms compliance with regulatory requirements and assures reliability for consumers and stakeholders. It is essential for industries such as pharmaceuticals, food, and manufacturing.

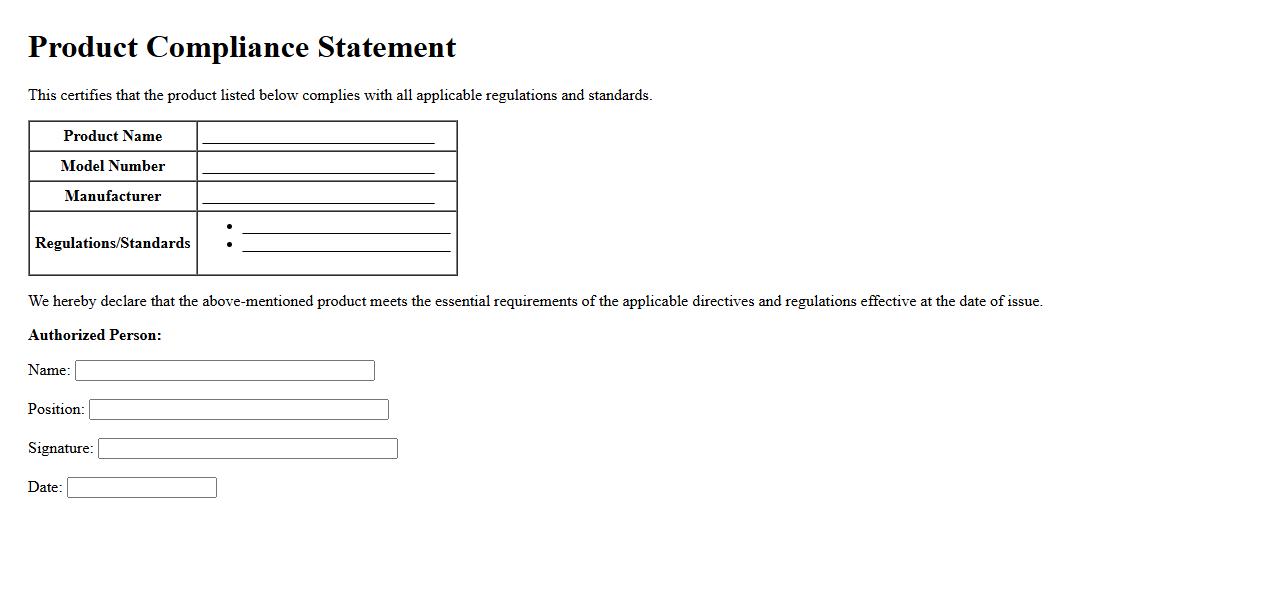

Product Compliance Statement

A Product Compliance Statement certifies that a product meets all relevant regulatory standards and requirements. This declaration ensures safety, quality, and legal adherence in various markets. It helps businesses maintain transparency and consumer trust.

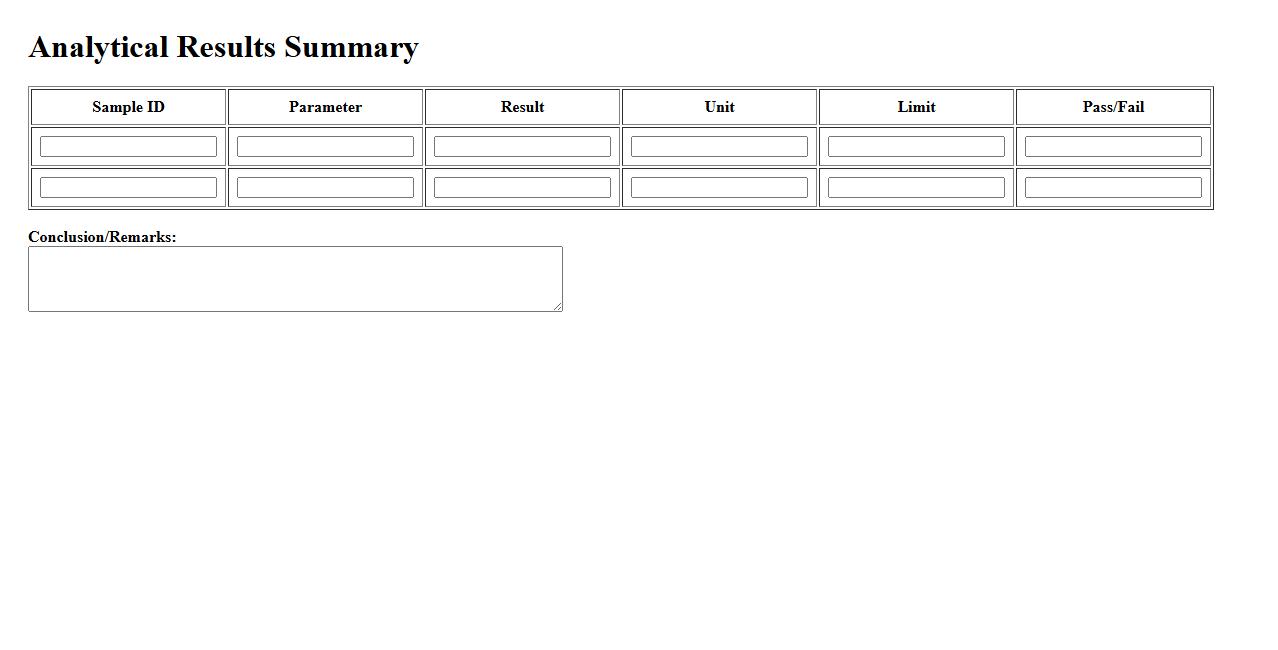

Analytical Results Summary

The Analytical Results Summary provides a concise overview of data findings and key insights derived from the analysis. It highlights significant trends, patterns, and anomalies to support informed decision-making. This summary ensures stakeholders can quickly grasp the essential outcomes without delving into detailed reports.

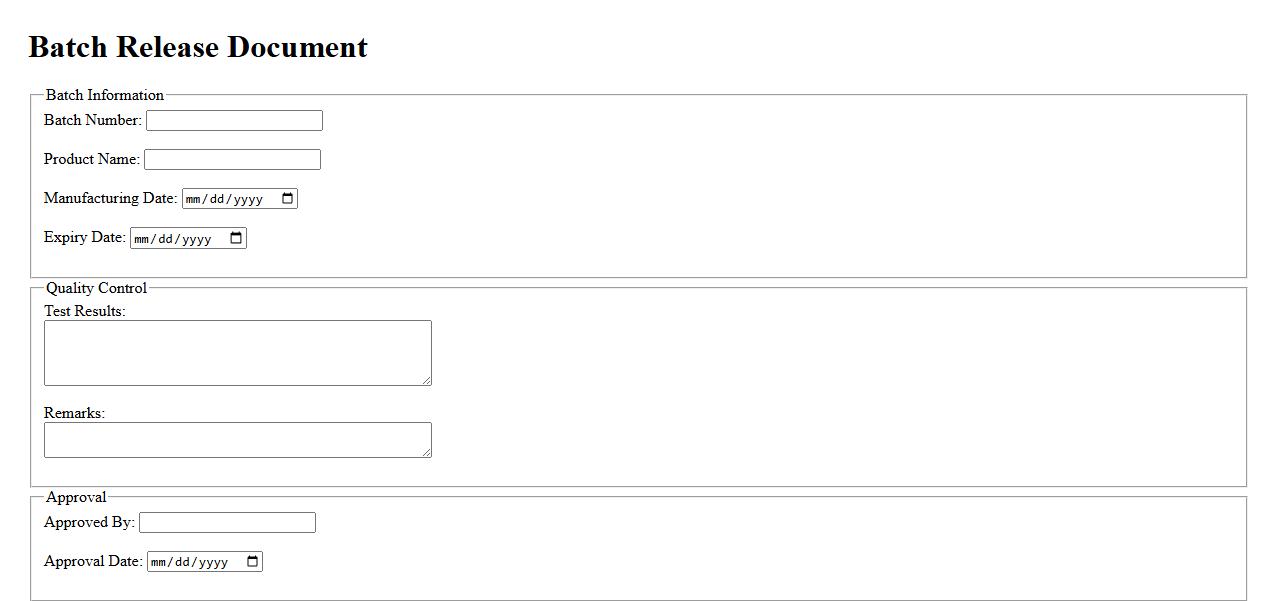

Batch Release Document

The Batch Release Document is a critical record used in manufacturing and quality assurance processes to verify that a product batch meets all specified criteria before distribution. It consolidates test results, inspection data, and compliance confirmations to ensure product safety and efficacy. This document serves as formal approval for releasing the batch to the market.

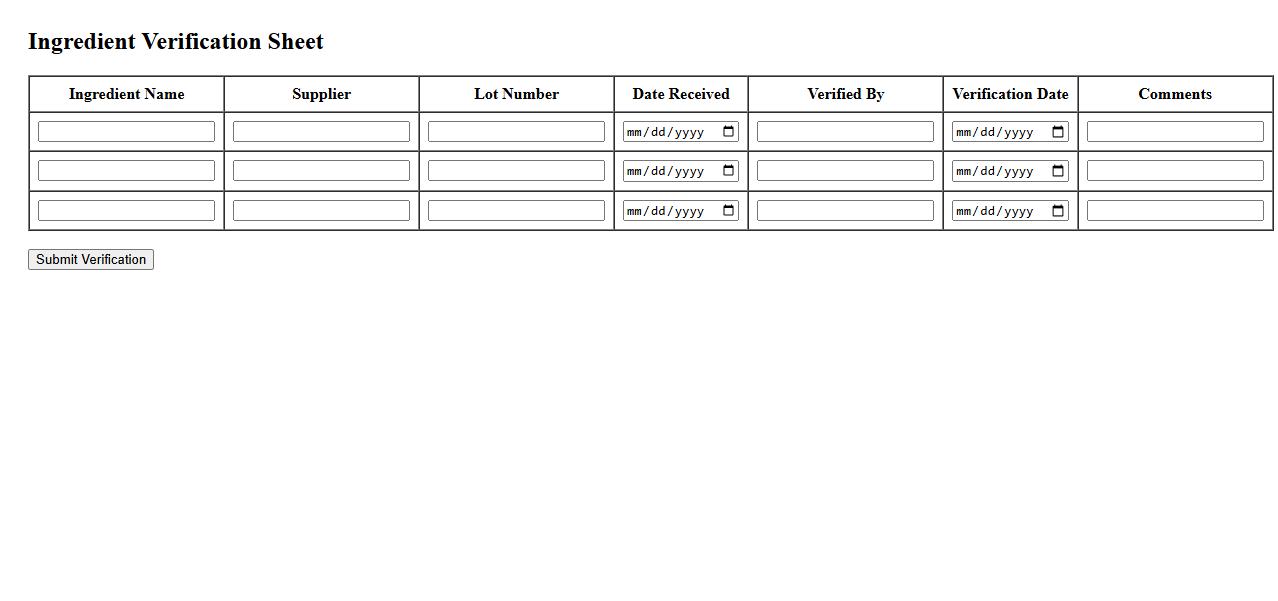

Ingredient Verification Sheet

The Ingredient Verification Sheet is a crucial document used to confirm the accuracy and authenticity of all ingredients in a product. It ensures compliance with safety standards and helps maintain product quality. This sheet is essential in industries such as food, pharmaceuticals, and cosmetics.

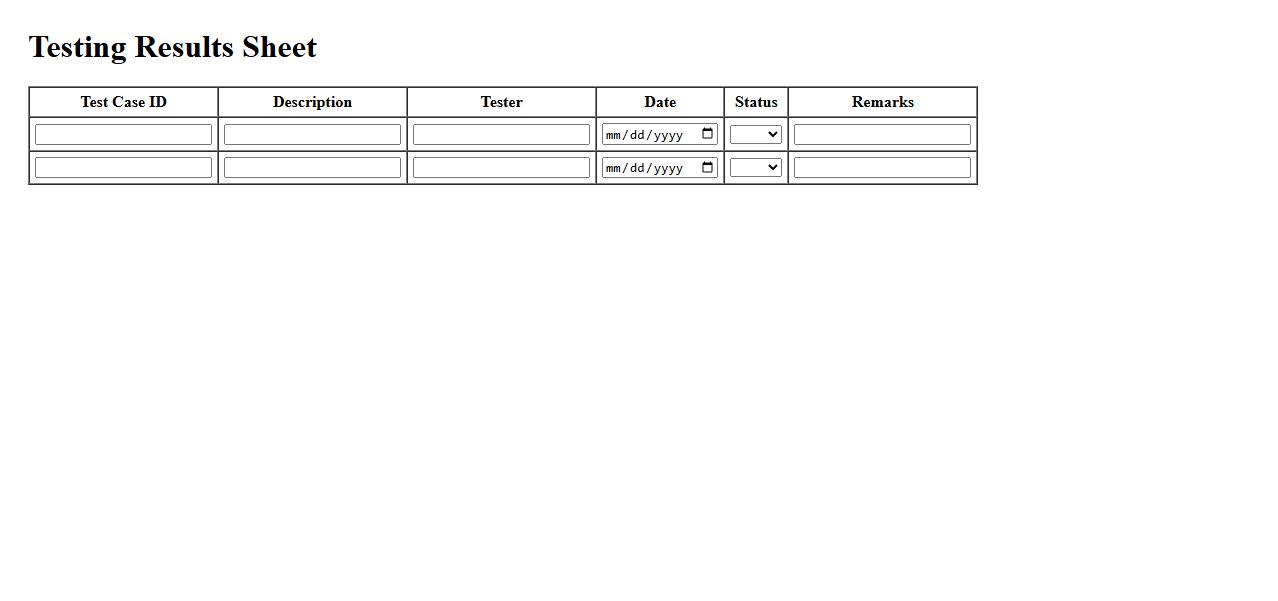

Testing Results Sheet

The Testing Results Sheet is a detailed document that records and organizes the outcomes of various tests performed. It ensures accurate tracking of performance metrics and helps in identifying potential issues. This sheet is essential for maintaining quality control and making informed decisions.

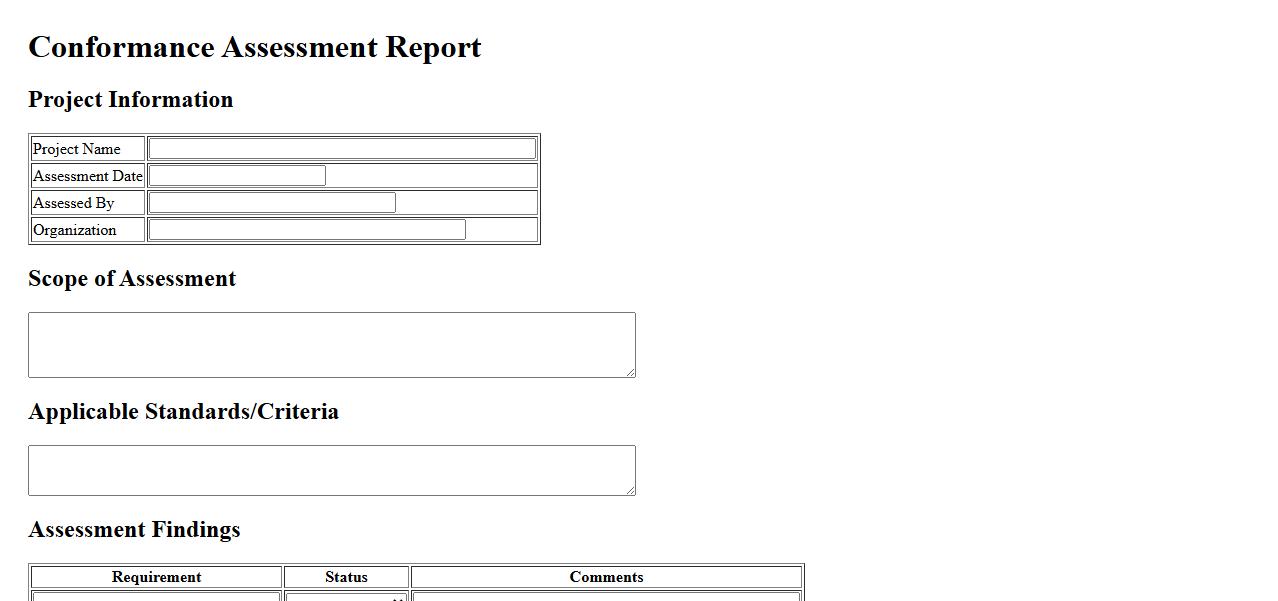

Conformance Assessment Report

The Conformance Assessment Report provides a detailed evaluation of a product or system's adherence to specified standards and requirements. It ensures transparency and reliability by documenting test results and compliance status. This report is essential for regulatory approval and quality assurance processes.

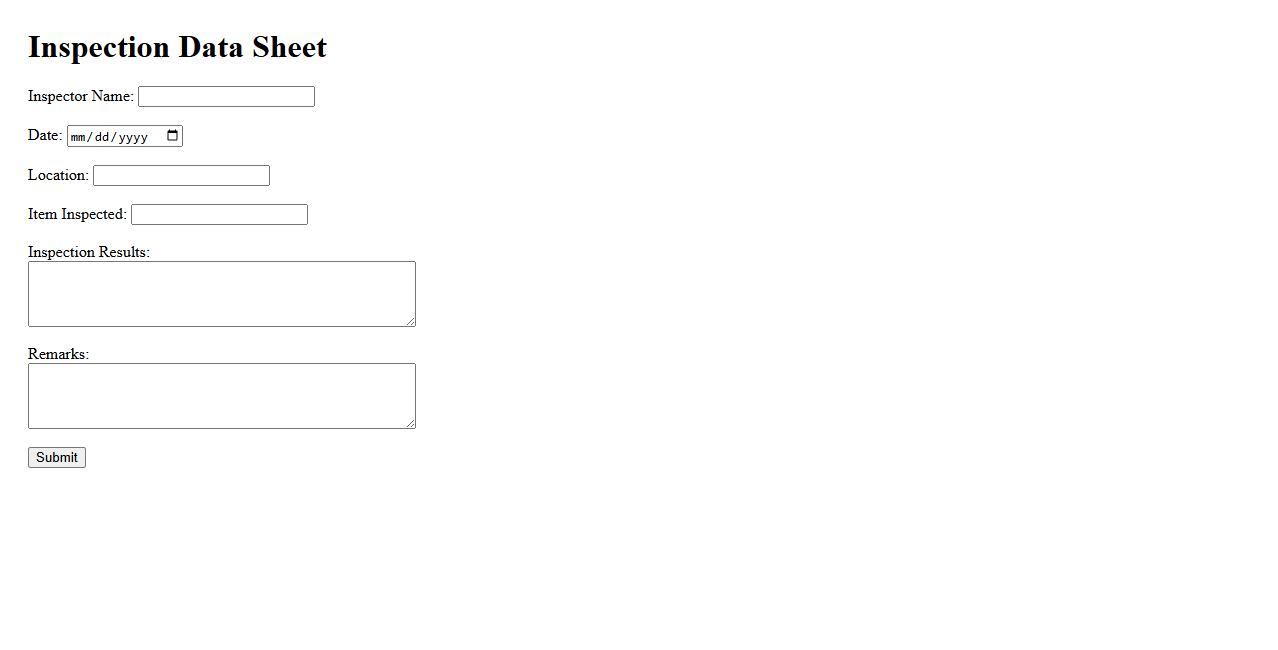

Inspection Data Sheet

An Inspection Data Sheet is a comprehensive document used to record the results of quality checks during production or maintenance. It ensures all parameters meet specified standards and helps identify any defects or deviations. This sheet is essential for maintaining product consistency and compliance with industry regulations.

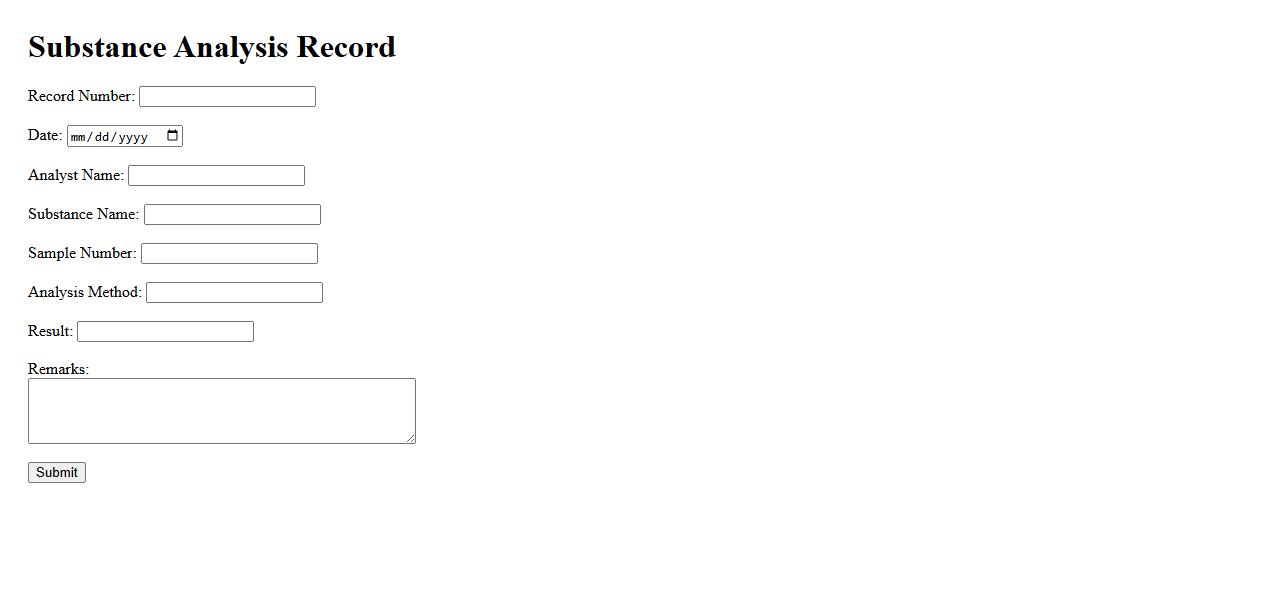

Substance Analysis Record

The Substance Analysis Record is a crucial document used to track the composition and properties of chemical substances. It ensures accurate identification and quality control during laboratory testing and industrial processes. This record enhances transparency and compliance with safety regulations.

What key components are typically included in a Certificate of Analysis (COA) document?

A Certificate of Analysis (COA) typically includes product identification details such as batch or lot number, manufacturing date, and expiration date. It provides a comprehensive summary of the test results against predefined specifications, including purity, potency, and contaminant levels. Additionally, the COA includes information about the testing methods used and the signature of the authorized personnel.

How does a Certificate of Analysis ensure product quality and safety?

The Certificate of Analysis serves as a formal document that verifies a product meets specific quality and safety standards before release. By comparing test results to accepted criteria, it guarantees the absence of harmful contaminants and confirms product efficacy. This process ensures consumers receive reliably safe and high-quality products.

What standards or regulations are referenced in a typical Certificate of Analysis?

A typical COA references industry standards such as pharmacopeial guidelines, ISO standards, and regulatory requirements set by organizations like the FDA or EMA. These references ensure that testing methods and quality parameters comply with legal and scientific benchmarks. This adherence helps maintain uniformity and trust in the product's quality across markets.

Who is responsible for issuing and validating a Certificate of Analysis?

The responsibility for issuing and validating a COA usually lies with a qualified quality control or quality assurance team within the manufacturing or testing laboratory. These professionals ensure the document's accuracy by reviewing all analytical data and confirming compliance with relevant standards. Their authorization is critical for the product's official release and market entry.

How can discrepancies in a Certificate of Analysis impact supply chain decisions?

Discrepancies in a COA can lead to significant supply chain disruptions, including delays in product release or rejection of shipments. Such inconsistencies may trigger additional testing or regulatory scrutiny, increasing operational costs and undermining supplier credibility. Consequently, accurate and reliable COAs are essential for smooth and efficient supply chain management.