A Report of Equipment Damage documents any physical harm or malfunction affecting machinery or tools during operation. It includes detailed descriptions, the extent of damage, and potential causes to facilitate timely repairs and prevent further issues. This report is essential for maintaining safety standards and ensuring efficient equipment management.

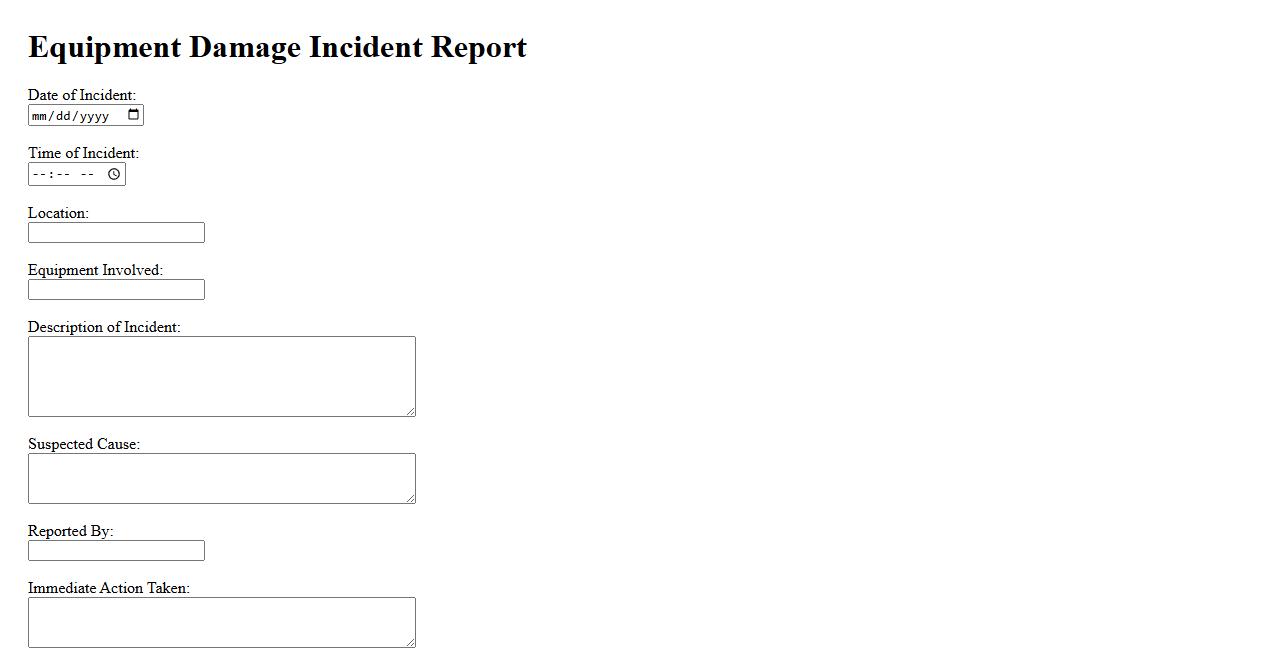

Equipment Damage Incident Report

The Equipment Damage Incident Report is a crucial document used to detail any harm sustained by machinery or tools during operations. It helps in recording the nature, cause, and extent of the damage to facilitate appropriate repair and preventive measures. Timely completion of this report ensures safety and maintains operational efficiency.

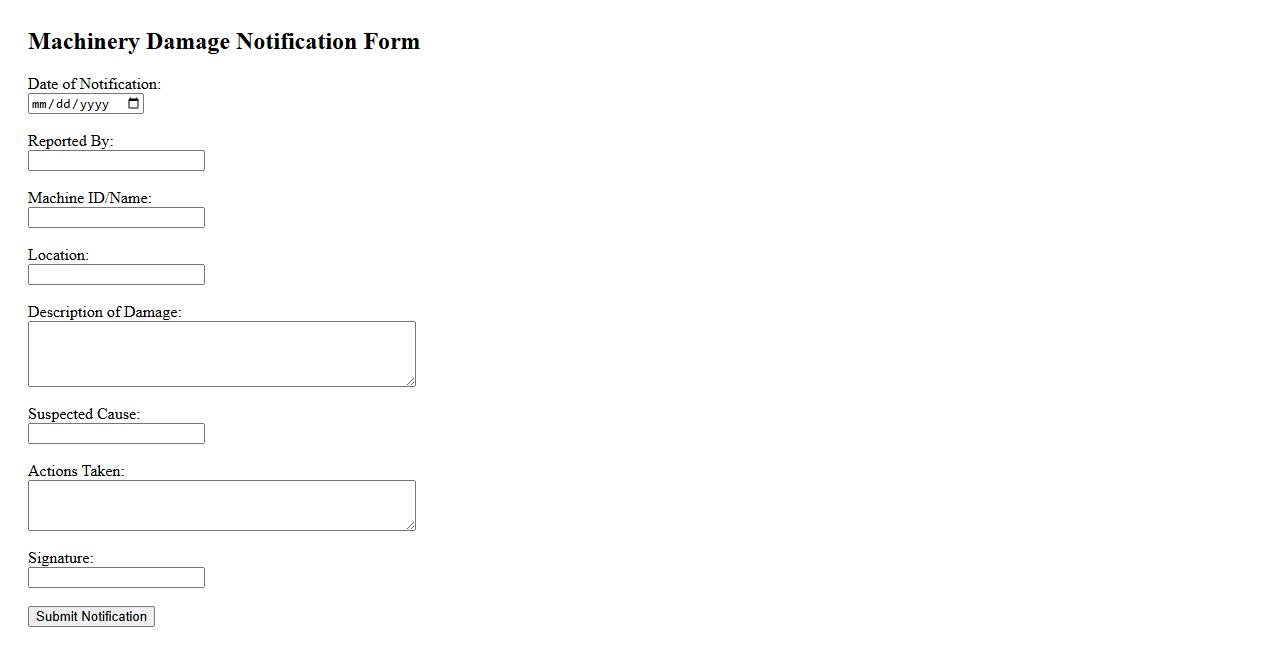

Machinery Damage Notification

Machinery damage notification is a critical communication process used to report and document any malfunction or damage to industrial equipment promptly. This ensures timely maintenance, minimizing downtime and preventing further damage. Efficient notification systems enhance operational safety and reliability in manufacturing environments.

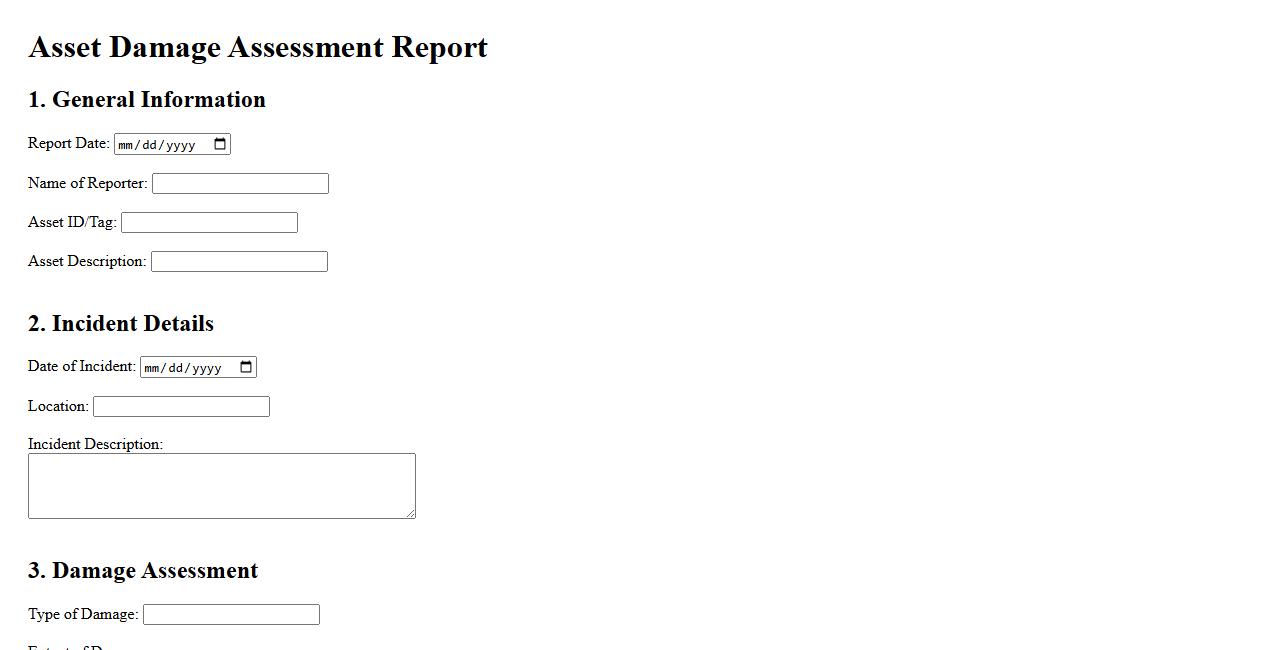

Asset Damage Assessment Report

The Asset Damage Assessment Report provides a detailed evaluation of physical damage to assets following an incident. It summarizes the extent of destruction, estimated repair costs, and necessary remediation measures. This report aids stakeholders in making informed decisions on recovery and insurance claims.

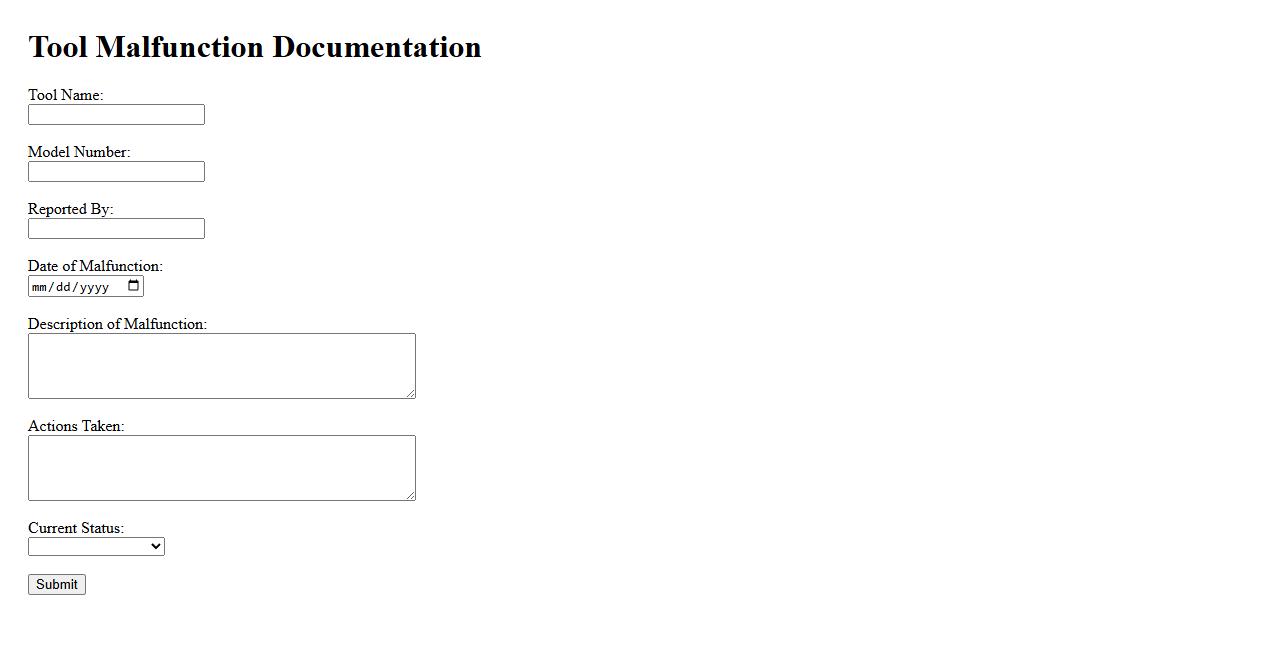

Tool Malfunction Documentation

Tool Malfunction Documentation is essential for accurately recording any issues or failures encountered during the use of equipment. This process ensures that all malfunctions are documented promptly, helping to identify patterns and prevent future breakdowns. Proper documentation aids in maintaining safety standards and improving overall operational efficiency.

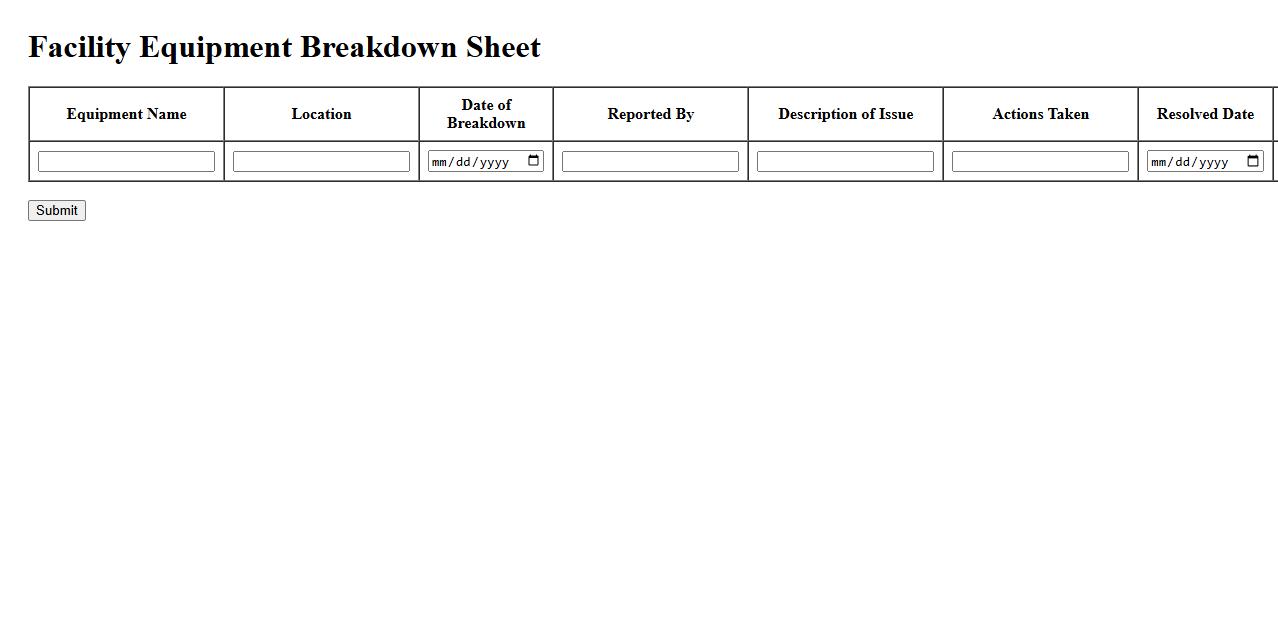

Facility Equipment Breakdown Sheet

The Facility Equipment Breakdown Sheet is a vital document used to track and report malfunctions or failures of machinery within a facility. It helps maintenance teams quickly identify issues, schedule repairs, and minimize downtime. Keeping this sheet updated ensures efficient equipment management and operational continuity.

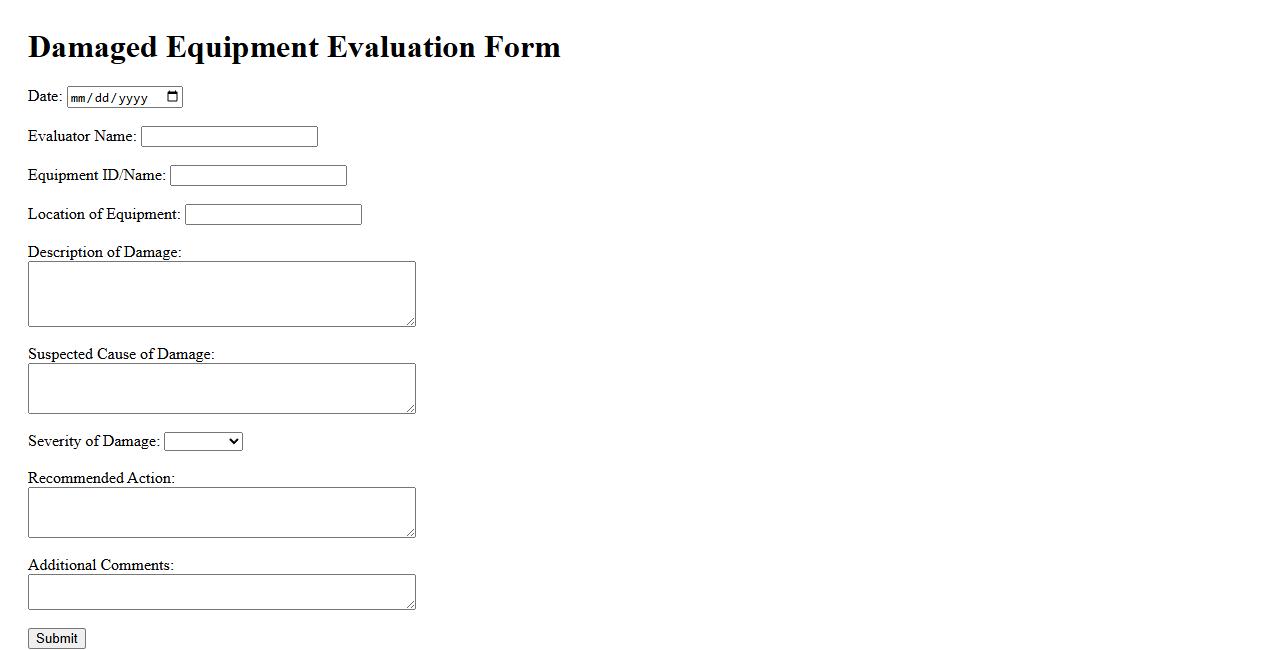

Damaged Equipment Evaluation Form

The Damaged Equipment Evaluation Form is essential for accurately documenting the condition of defective machinery or tools. This form helps track damage details, assess repair needs, and facilitate timely maintenance or replacement. Utilizing this evaluation ensures safety and operational efficiency in the workplace.

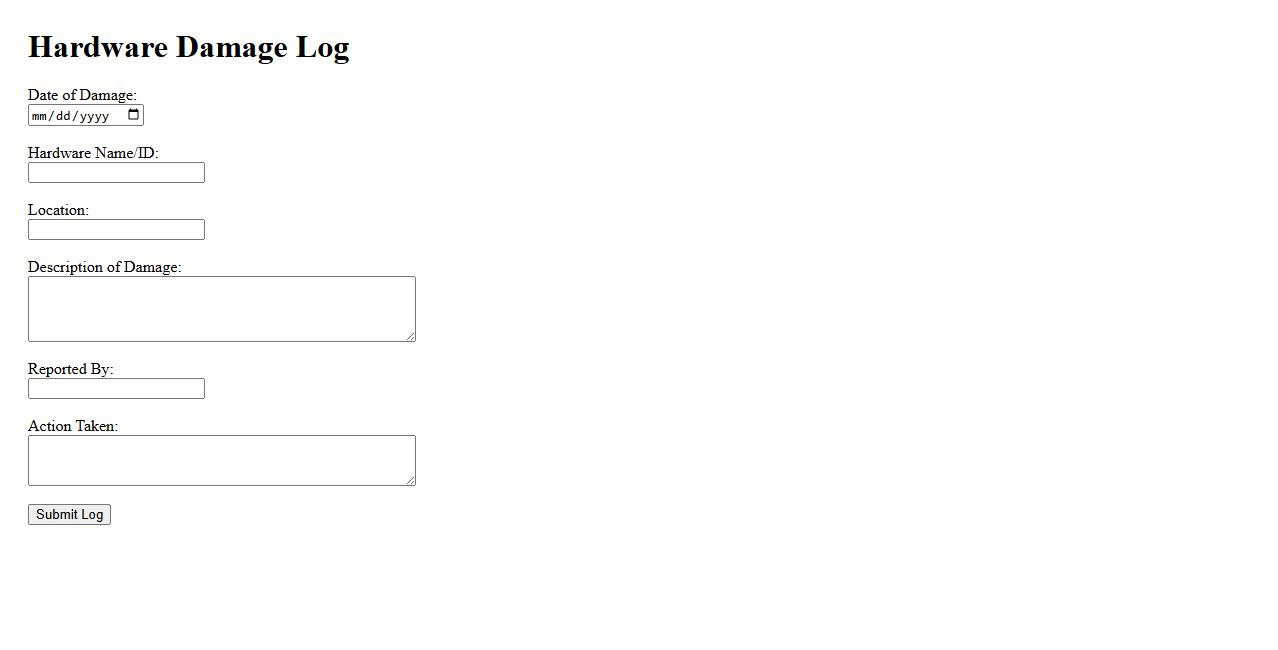

Hardware Damage Log

The Hardware Damage Log is a critical tool used to record and monitor any physical damage to computer equipment and devices. It helps organizations track repair history and identify recurring issues to prevent future breakdowns. Maintaining this log ensures timely maintenance and extends the lifespan of hardware assets.

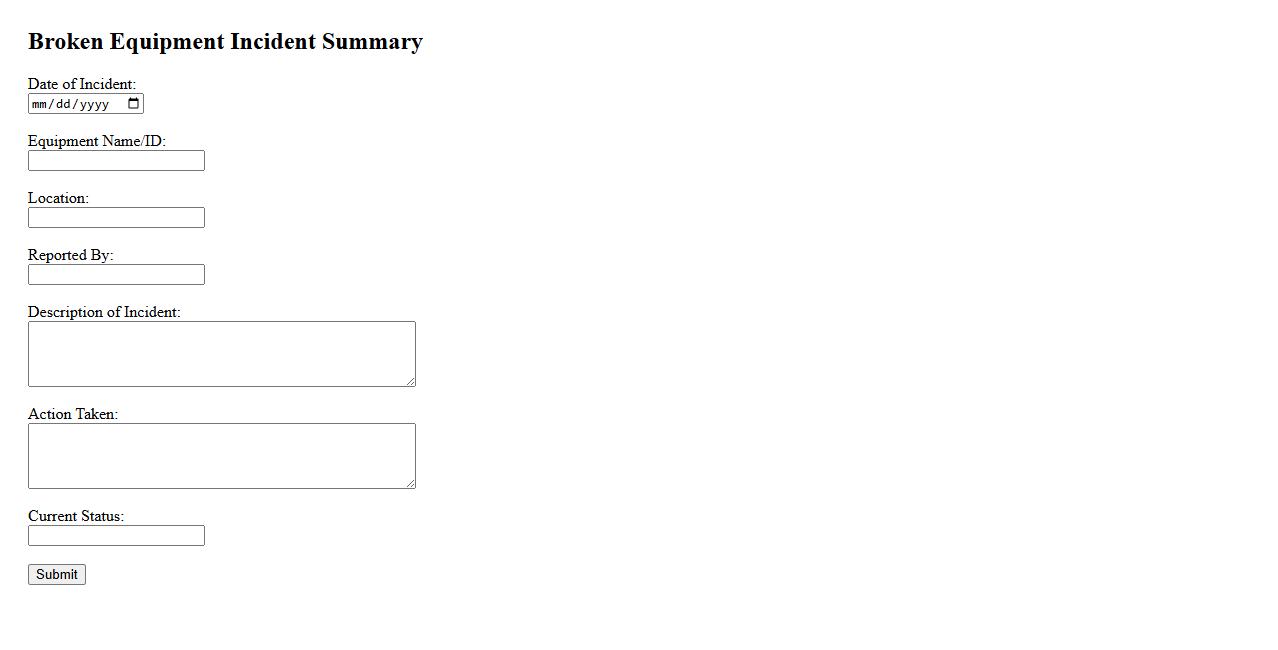

Broken Equipment Incident Summary

The Broken Equipment Incident Summary provides a detailed overview of all reported equipment failures within a specified period. It highlights the causes, impacts, and corrective actions taken to prevent future occurrences. This summary is essential for maintaining operational safety and efficiency.

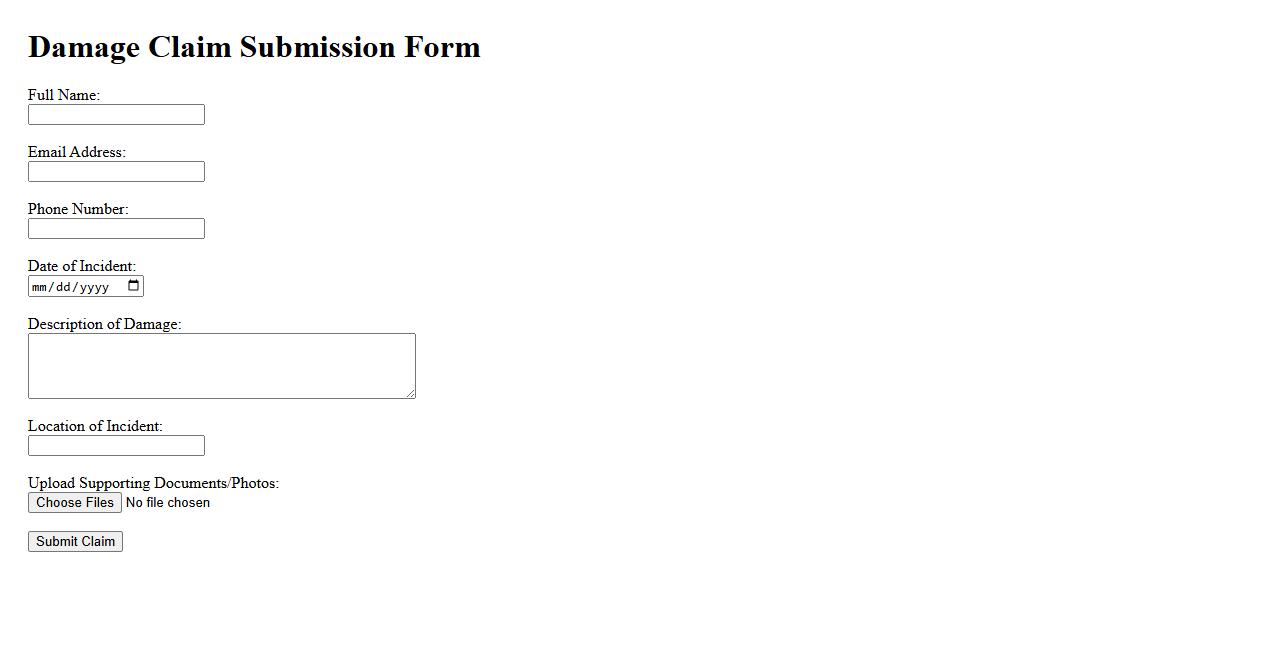

Damage Claim Submission Form

The Damage Claim Submission Form allows customers to report and document any damages efficiently. This form ensures accurate information is collected to process claims promptly. It simplifies the resolution process for both the customer and the service provider.

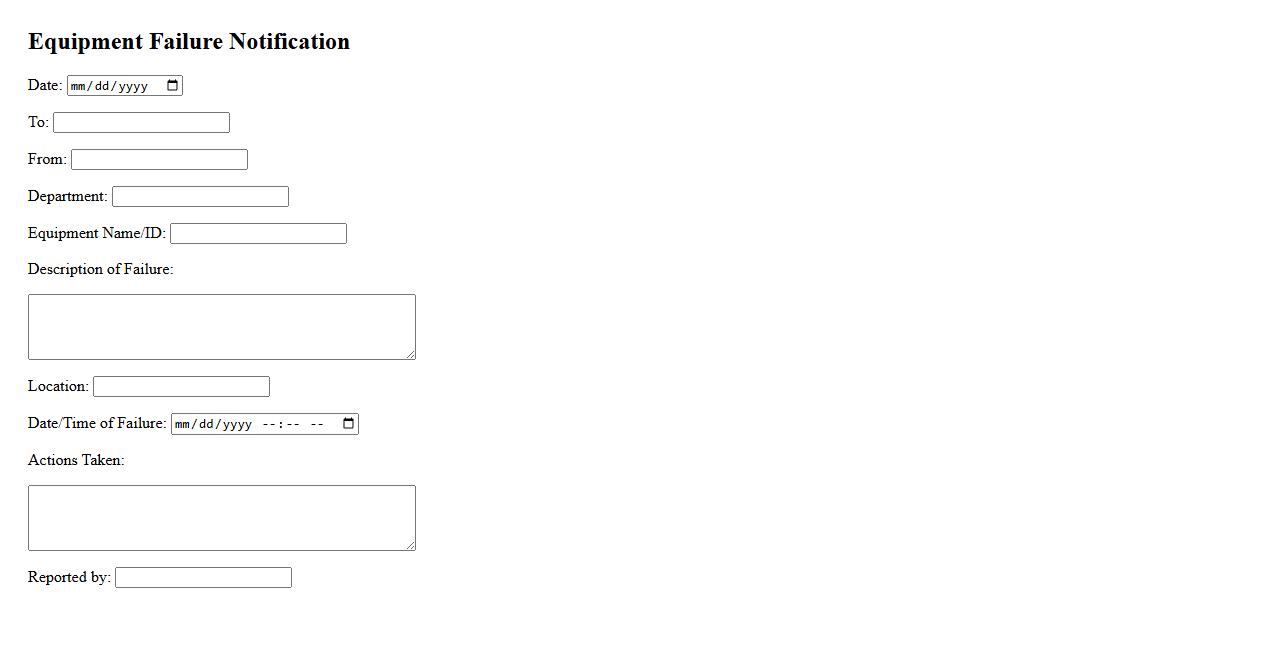

Equipment Failure Notification

Equipment Failure Notification alerts users immediately when machinery or devices malfunction, ensuring prompt attention and minimizing downtime. This system enhances safety and operational efficiency by providing timely updates. Early detection helps prevent costly repairs and production delays.

Specific Equipment Reported as Damaged

The hydraulic pump in the main production line is the equipment reported as damaged. Additionally, several control valves connected to the pump were found malfunctioning. These components are critical to the system's overall operation and efficiency.

Date and Time of the Reported Equipment Damage

The damage was reported on April 15, 2024, at approximately 09:30 AM. This timestamp correlates with the morning shift inspection. Precise documentation of the timing aids in tracing the incident timeline effectively.

Cause or Suspected Cause of the Equipment Damage

The suspected cause of the damage is overheating due to insufficient lubrication in the hydraulic pump. Preliminary investigations suggest a failure in the automatic lubrication system. This issue likely led to mechanical stress and subsequent component failure.

Who Identified and Reported the Equipment Damage

The damage was initially identified by the maintenance supervisor during a routine equipment check. Following the observation, the supervisor promptly reported the issue to the operations manager. This quick response helped initiate immediate corrective measures.

Immediate Actions Taken Following the Discovery of the Damage

Upon discovery, the affected hydraulic pump was immediately shut down to prevent further damage. A maintenance team was dispatched for a detailed inspection and repair. In addition, production was temporarily rerouted to minimize operational disruption.