A Certificate of Calibration is an official document that verifies the accuracy and precision of a measuring instrument against recognized standards. It provides detailed information about the calibration process, including the date, equipment used, and results obtained. This certificate ensures compliance with quality control requirements and supports reliable data in various industries.

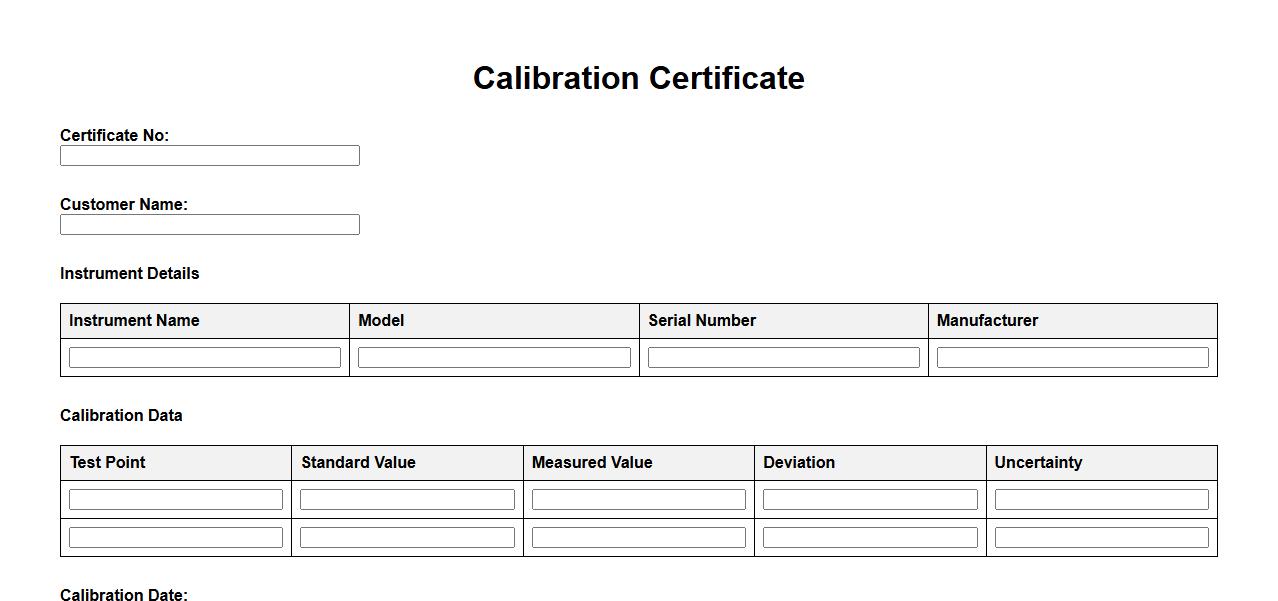

Calibration Certificate

A Calibration Certificate is an official document verifying the accuracy and precision of measuring instruments. It ensures that equipment meets specified standards and is suitable for its intended use. This certificate provides traceability to national or international measurement standards.

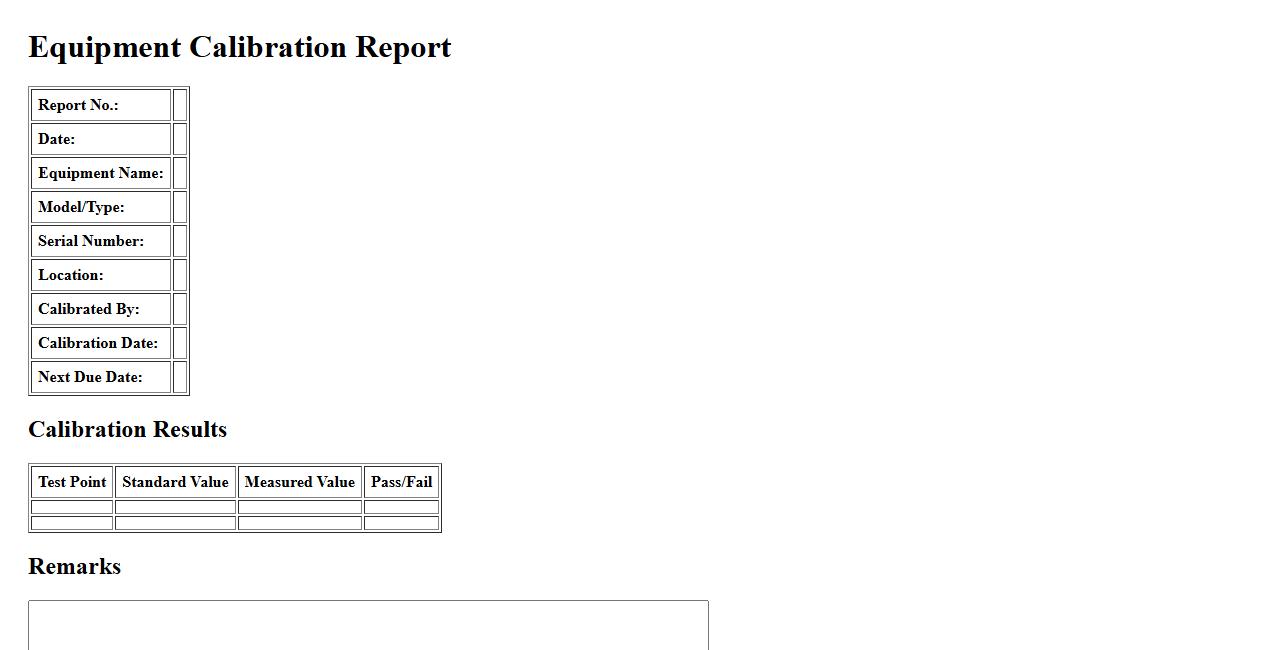

Equipment Calibration Report

An Equipment Calibration Report documents the process and results of calibrating measurement instruments to ensure accuracy and reliability. This report includes detailed information about the equipment tested, calibration methods used, and any adjustments made. Regular calibration helps maintain quality standards and compliance in various industries.

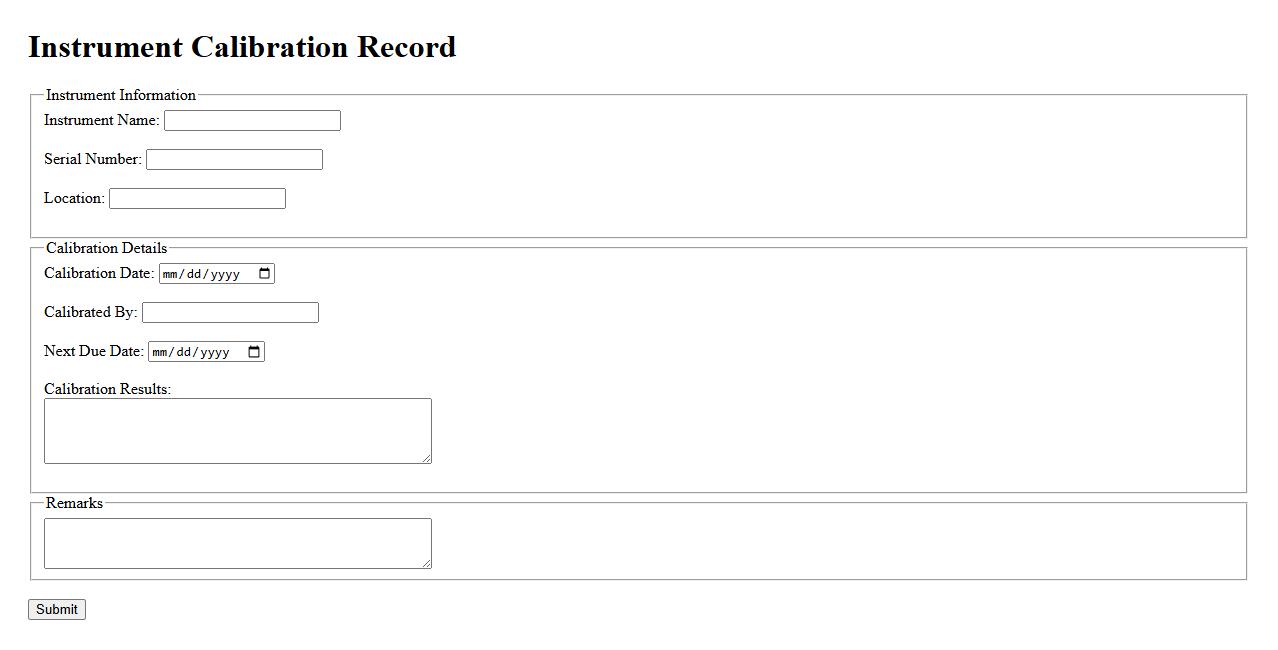

Instrument Calibration Record

An Instrument Calibration Record is a detailed document that tracks the accuracy and performance of measuring instruments over time. It ensures instruments meet required standards by recording calibration dates, results, and technician notes. Maintaining this record is essential for quality control and regulatory compliance.

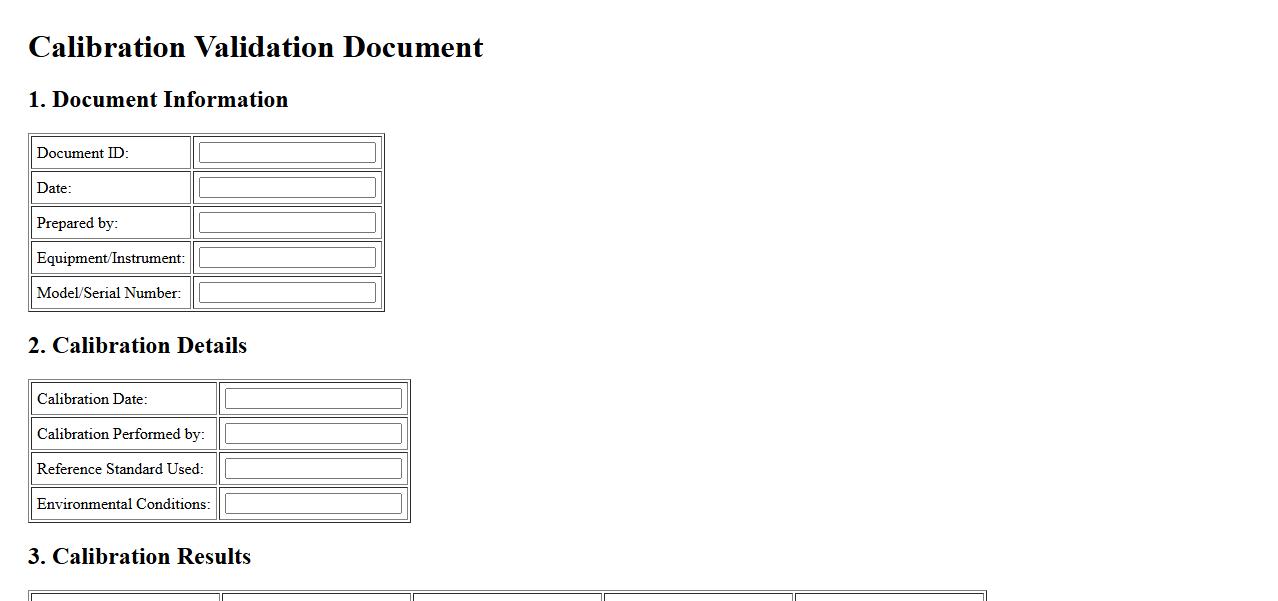

Calibration Validation Document

The Calibration Validation Document ensures that all measurement instruments meet specified standards and operate accurately. It provides a detailed record of the calibration process, confirming compliance with industry regulations. This document is essential for maintaining quality control and reliability in testing procedures.

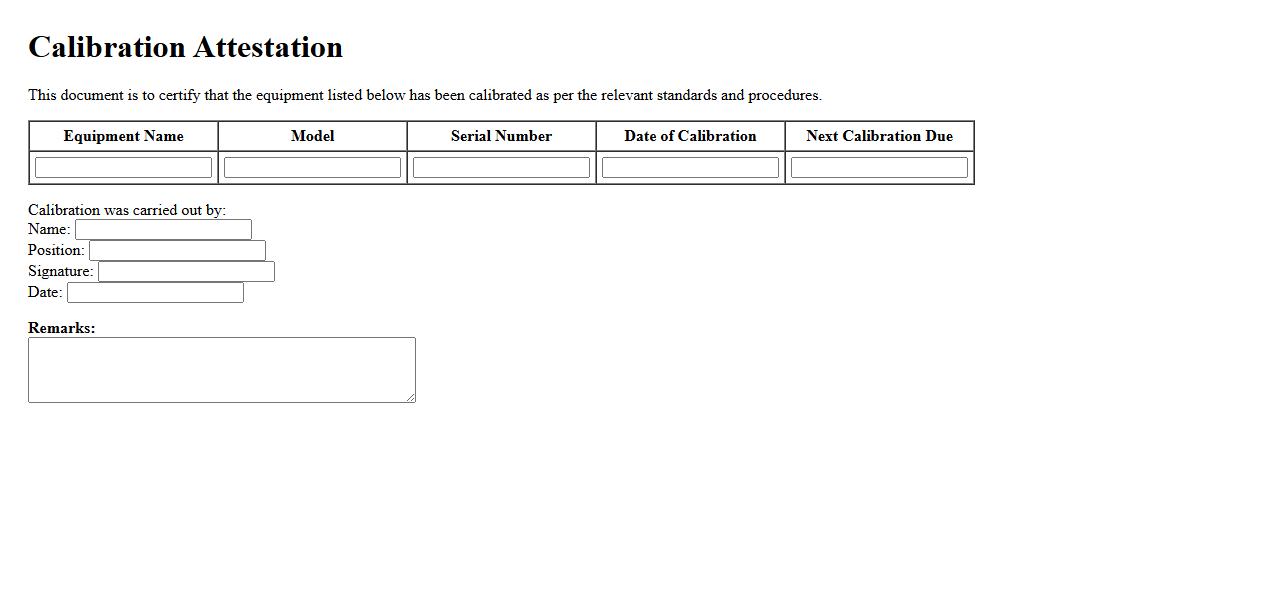

Calibration Attestation

Calibration Attestation is a formal document confirming that measurement equipment has been calibrated according to specified standards. It ensures accuracy and traceability in measurements, providing confidence in the reliability of results. This attestation is essential for maintaining quality control in various industries.

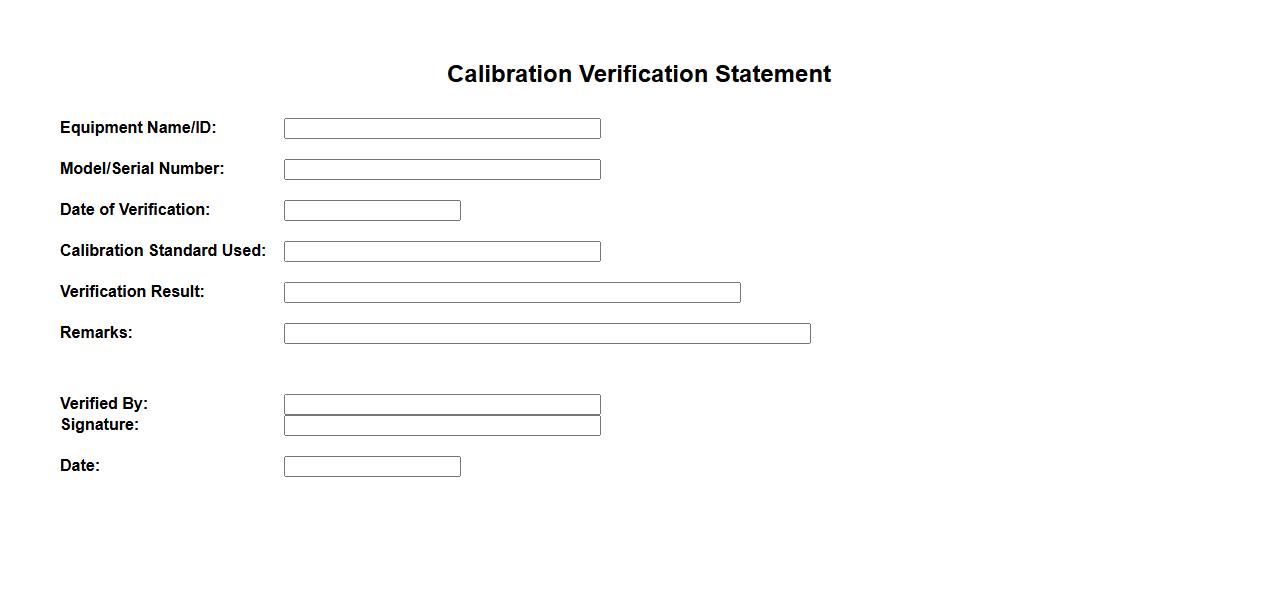

Calibration Verification Statement

The Calibration Verification Statement confirms that measurement instruments have been tested and meet required standards. This document ensures accuracy and reliability in measurements, supporting quality control processes. It is essential for maintaining compliance with industry regulations and standards.

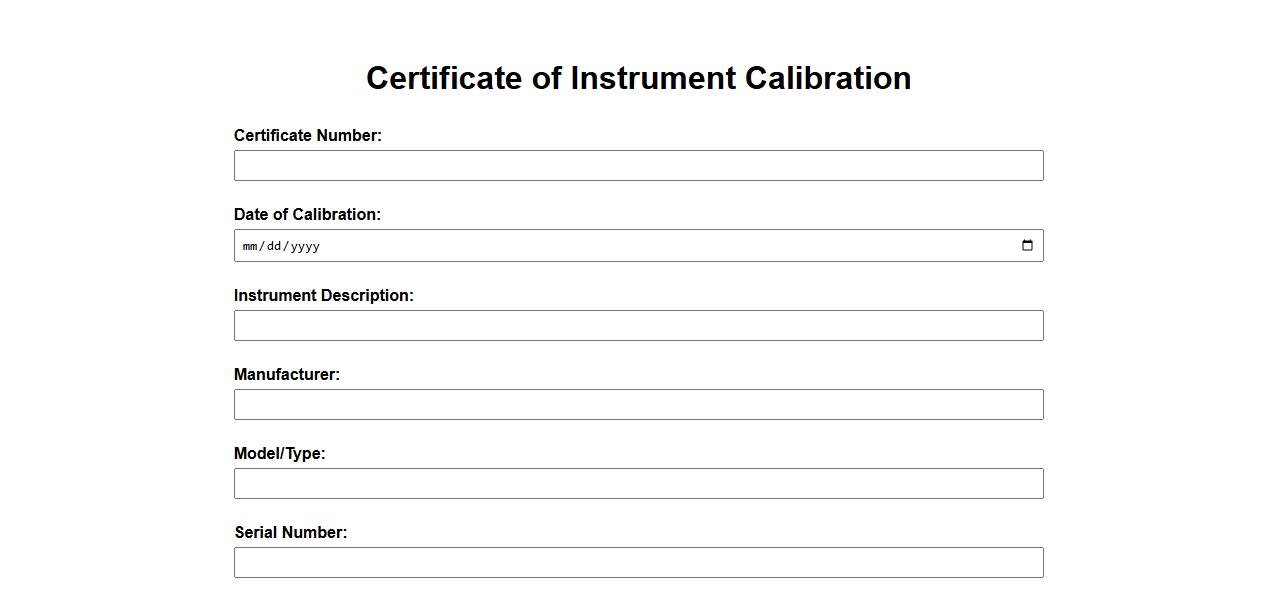

Certificate of Instrument Calibration

A Certificate of Instrument Calibration verifies that measuring instruments have been tested and adjusted to meet industry standards. It ensures the accuracy and reliability of the equipment used in various applications. This document is essential for maintaining quality control and compliance with regulatory requirements.

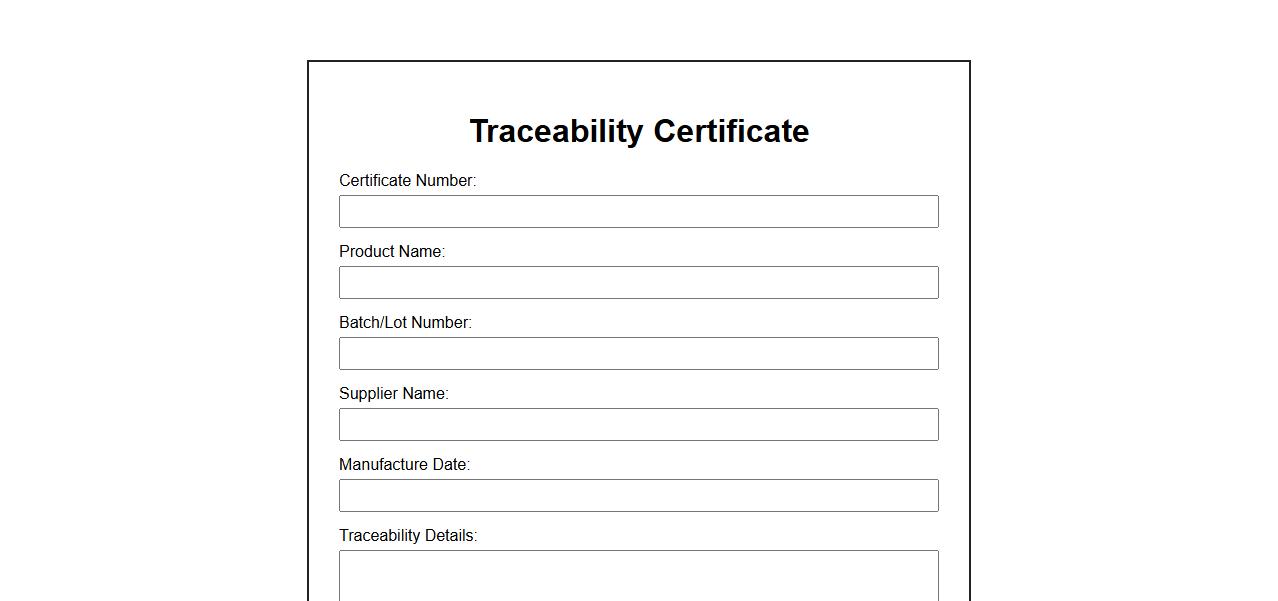

Traceability Certificate

A Traceability Certificate ensures that a product's origin and history can be accurately tracked throughout the supply chain. This certificate guarantees transparency and authenticity by documenting each step from production to delivery. It is essential for quality control and regulatory compliance in various industries.

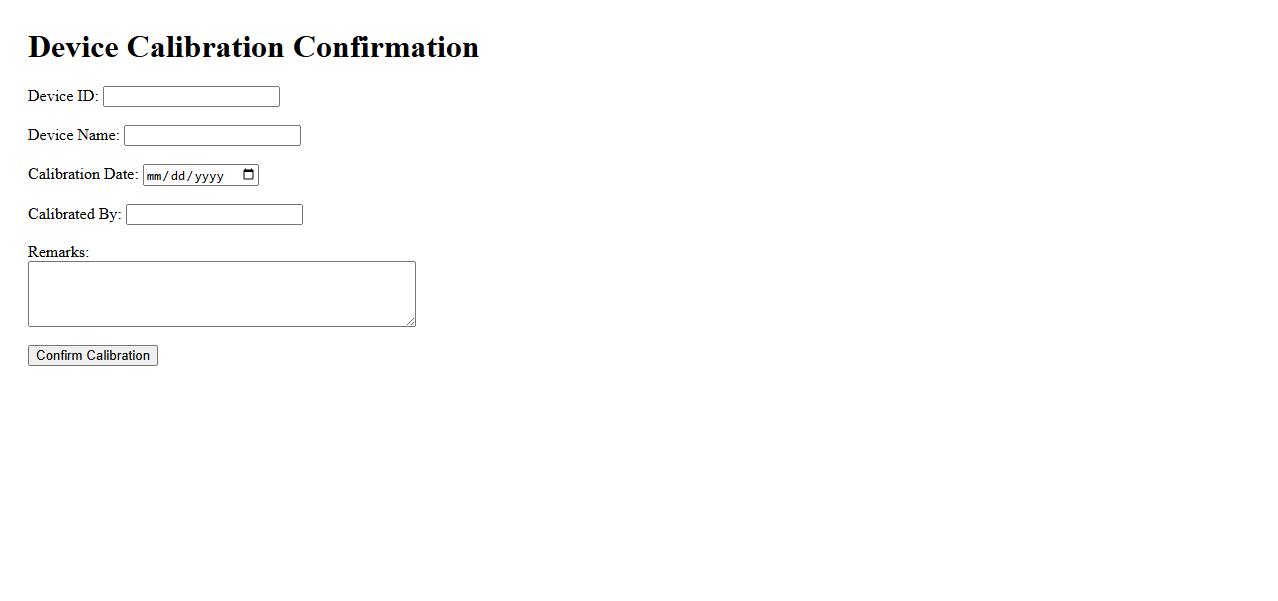

Device Calibration Confirmation

The Device Calibration Confirmation ensures that all instruments are accurately adjusted to meet industry standards. This process guarantees reliable and precise measurements, enhancing overall performance and safety. Regular calibration confirmation helps maintain device integrity and compliance.

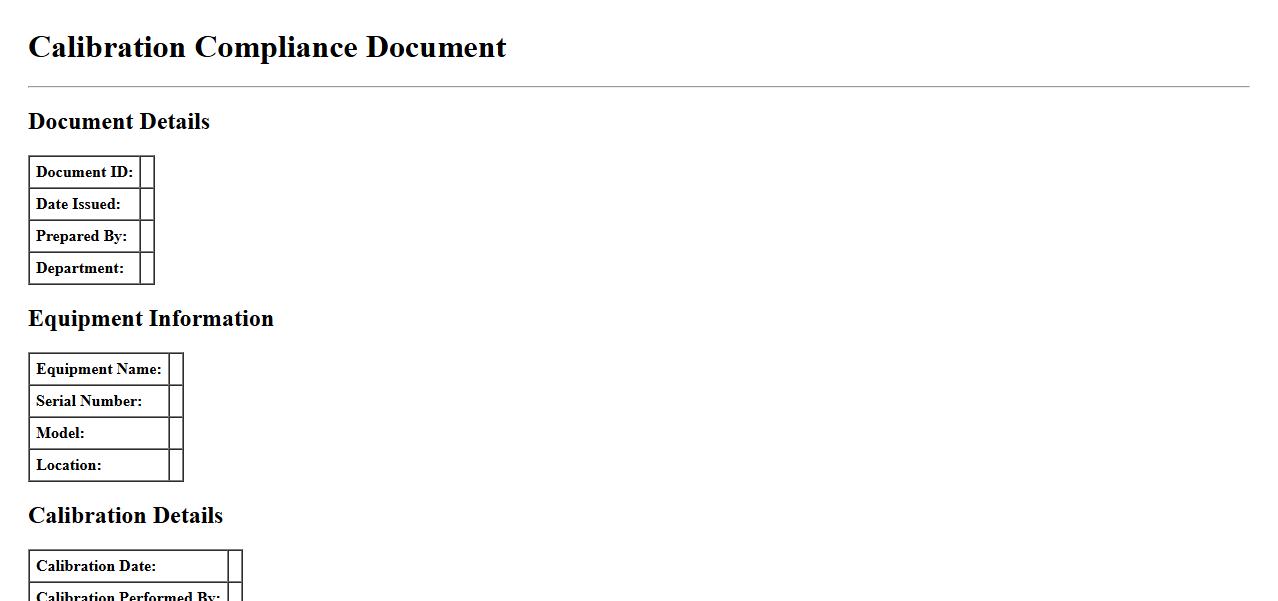

Calibration Compliance Document

The Calibration Compliance Document ensures that all measurement instruments meet required standards and regulations. It provides proof of accurate calibration processes, supporting quality control and regulatory audits. Maintaining this document is essential for consistent product reliability and industry compliance.

What information does a Certificate of Calibration typically include?

A Certificate of Calibration typically includes the identification details of the instrument being calibrated, such as serial number and model. It also records the date of calibration, environmental conditions, and the calibration results compared against a reference standard. Additionally, it contains the name of the calibration laboratory and the technician responsible for the process.

How does a Certificate of Calibration ensure traceability to national or international standards?

The certificate ensures traceability by linking the calibration to recognized national or international standards through documented references. This traceability is achieved by using reference materials or equipment that have been calibrated against standards maintained by organizations like NIST or ISO. It guarantees that the calibration process is reliable, consistent, and globally accepted.

What is the validity period indicated on a Certificate of Calibration?

The validity period on a Certificate of Calibration specifies the time frame during which the calibration results are considered accurate and reliable. It typically ranges from six months to one year, depending on the instrument type and usage conditions. After this period, recalibration is necessary to maintain precision and compliance.

Who is authorized to issue a Certificate of Calibration?

A Certificate of Calibration must be issued by an accredited calibration laboratory or a qualified calibration technician authorized by the calibration body. These entities comply with international quality standards such as ISO/IEC 17025. The authorization ensures the calibration results are credible and recognized.

What does the uncertainty measurement signify in a Certificate of Calibration?

The uncertainty measurement in a Certificate of Calibration quantifies the doubt associated with the calibration results. It defines the range within which the true value of the measurement lies with a specified level of confidence. This information is crucial for understanding the reliability and accuracy of the instrument's measurements.